Business zone

Make your ice trustworthy!

Criteria

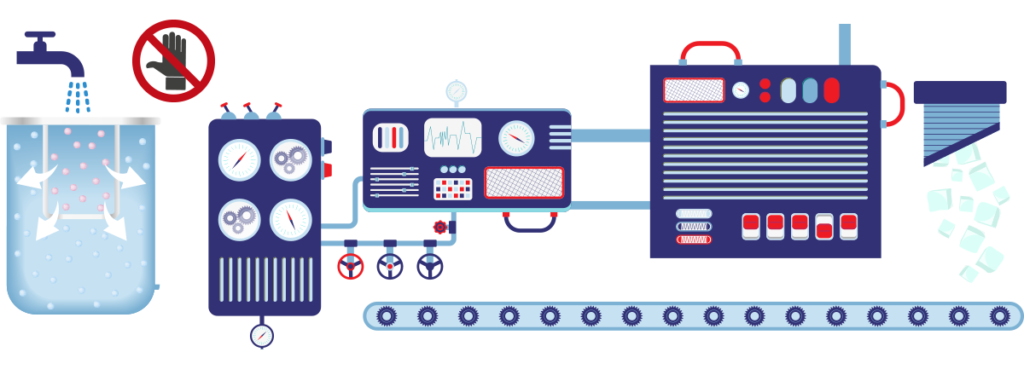

With safety and high product quality in mind, together with the Polish certification body TÜV Rheinland, we have developed criteria with critical points that have a major impact on the final product. To receive membership and use the Certified Food Grade Ice mark on packaging, vehicles, and company documentation, you need to meet all the requirements set by the association and the certification body, pass an audit, and make a written commitment to comply with the association’s constitution and objectives.

Below, you will find the key criteria:

Raw materials: |  Water: |  Packaging: |  Product designation: |

|---|---|---|

– Osmotic water | – Packaging approved for food contact, confirmed by current migration and specific migration test results and the manufacturers’ declaration of conformity | – Durable designation ensuring product traceability from conception to retail sale

|

– UV water sterilisation immediately before freezing for the final product | – Providing adequate strength in sub-zero temperatures to prevent spontaneous and uncontrolled unsealing

| – Full traceability system for all parts of the finished product; traceability and recall of defective products

|

– Production with a system to prevent water stagnation, which is conducive to the development of microorganisms

|

Safety and hygiene: |  Air: |  Premises: |  Clean machinery and equipment: |

|---|---|---|

– UV air sterilisation in sensitive areas of the open product

– controlled temperature of <5 °C in the product transport and collective packaging area <5°C w obszarze transportu i pakowania produktu w opakowania zbiorcze – controlled humidity of <60% in the packaging storage areas <60% wilgotności w obszarach składowania opakowań | – separate clean production area with a disinfection lock to protect against external hazards | – Industrial ice machines: • Regular disinfection (at least once a month and after any downtime lasting more than 96 h) – Ice cube makers: • Regular disinfection (at least once a week and after any downtime lasting more than 48 h) – Conveying and packaging lines in direct contact with the open product: • Ongoing disinfection (once a fortnight and after any downtime lasting more than of 96 hours) • Thorough disinfection of the production area (four times a year/once a quarter) – Cleanliness check: • Random swabs from surfaces of machinery and equipment in direct contact with the open product (once a fortnight) • Swabs from all equipment in direct contact with the open product: testing of swabs for bacteria from the production line (four times a year/once a quarter) |

Continuous surveillance of product safety for consumers with a metal detector in the production line and a system to identify glass and plastic in the production area

Ongoing monitoring of the weight of each product unit package

Laboratory testing of the product (at least once a month and after each process downtime)

Testing of raw and production water (at least once a quarter)

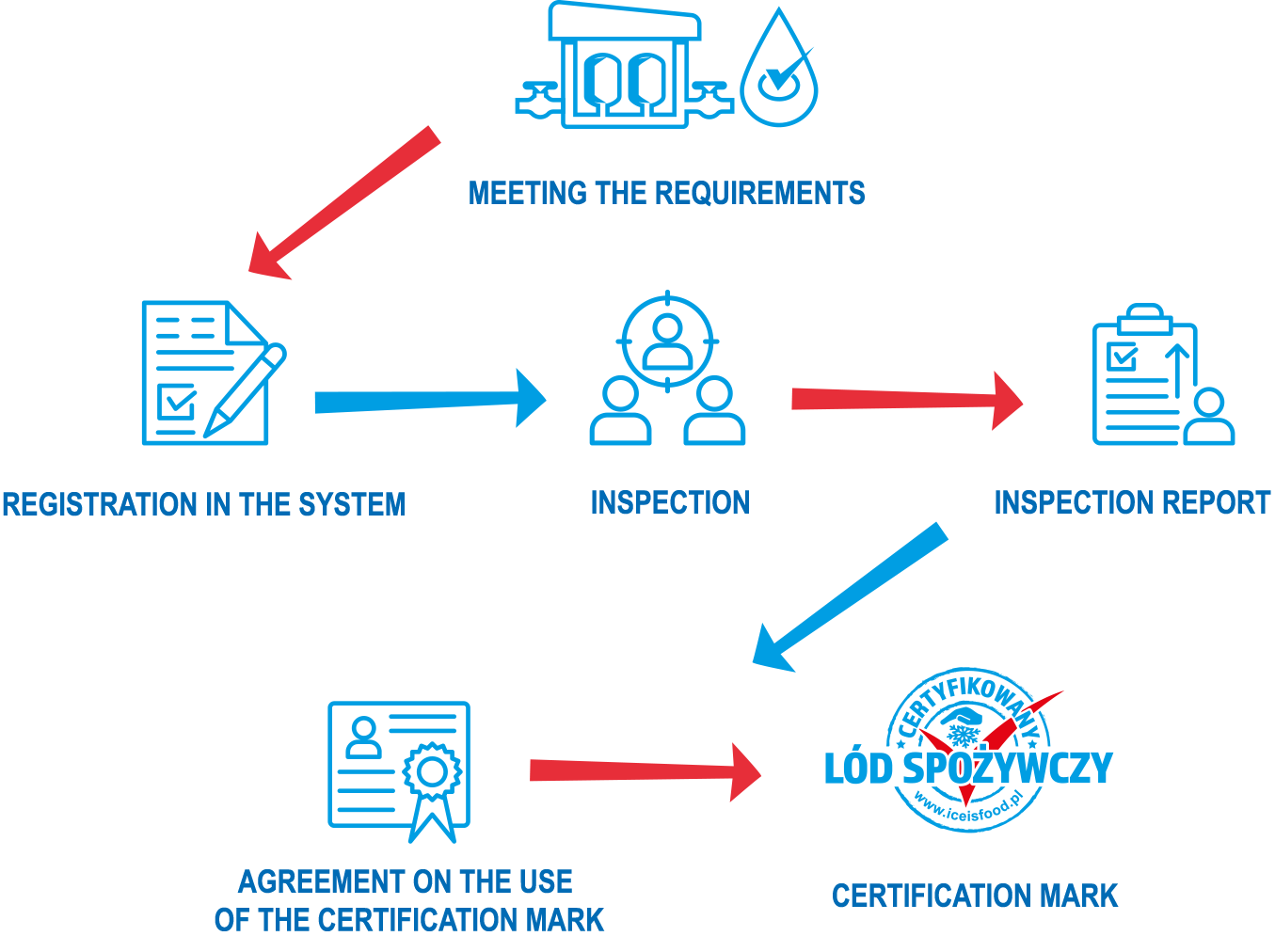

Certification process

Following the decision to join the association, you will start to prepare for certification under the guidance of a qualified advisor. When the preparation process is complete, contact the certification body and arrange an audit date. The audit will check if you comply with the guidelines.

At the end of the audit, you will receive an audit report from the certification body. If irregularities have been found during the audit, you will need to rectify them within a period set by the certification body and repeat the audit. If you pass the audit, you will become an eligible member of the association and will be able to use the Certified Food Grade Ice mark.

If you are interested in becoming a member of the association, please send us a message via the Contact tab or contact us by e-mail at info [at] iceisfood.pl. We will be happy to answer any questions and explain the membership rules, the stages of the certification process, and the rights and obligations of members.

Stowarzyszenie Producentów

i Operatorów Certyfikowanego Lodu Spożywczego, Numer KRS: 0000784552,

REGON: 383424111, NIP: 7010927104

00-630 WARSZAWA, ul. POLNA 24 lok. 7